How much do you know about watch strap?

For anyone who’s really into watches, there’s one thing we all agree on — changing watch straps is an essential part of the fun.

A new watch bands

can completely transform the look and feel of the same watch — sometimes it even feels like you’ve got a brand-new timepiece on your wrist.

Unless you’ve got an unlimited budget, most of us can’t afford to buy new watches all the time just for that thrill.

That’s why experimenting with different watch straps becomes the smarter (and more satisfying) way to enjoy our collection.

So in this article, we will sharing some of my thoughts and experiences, hoping they’ll help fellow watch lovers make better choices.

Common watch strap types

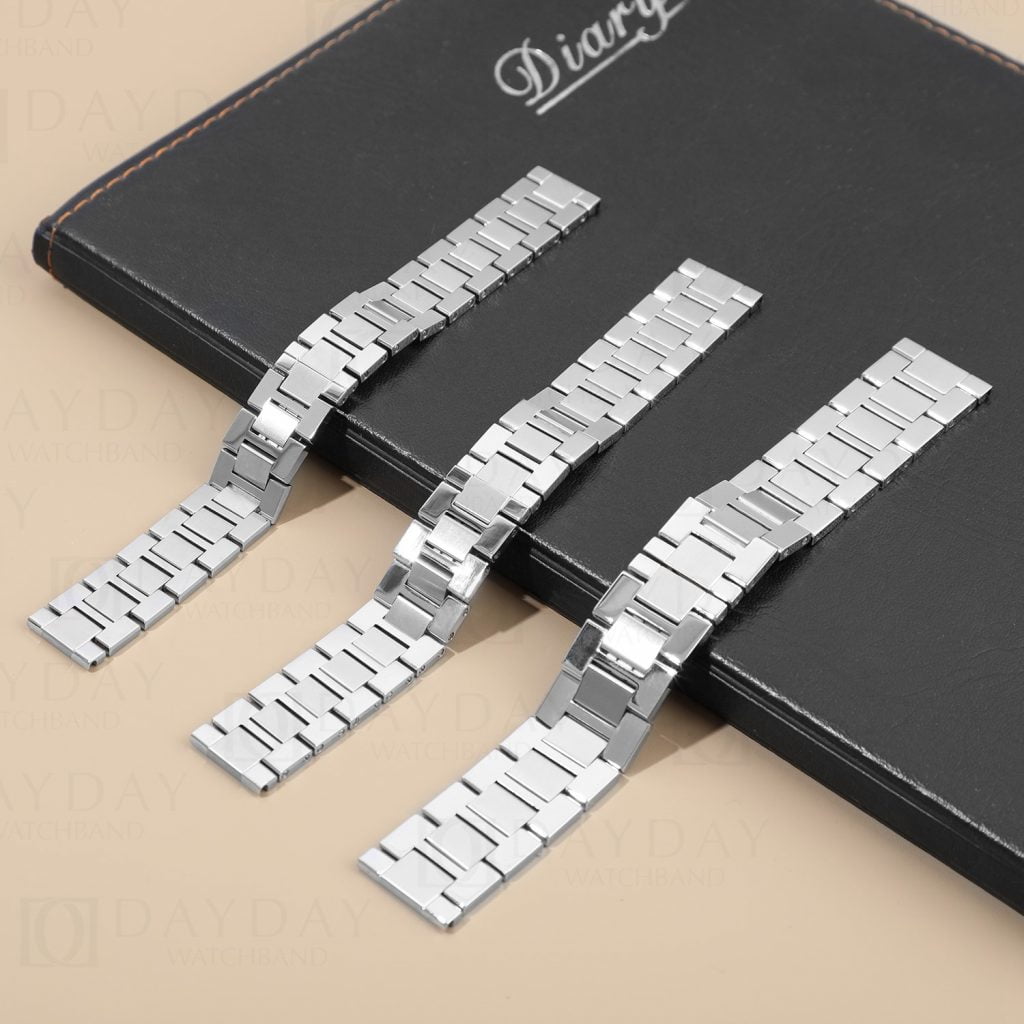

Watch straps come in many types — the most common being metal bracelet, leather watch strap, rubber strap, and sometimes fabric watch band.

Metal bracelet are the easiest to live with: durable, water-resistant, sweat-proof, and seamlessly integrated with the case. Even after years of wear, a bit of polishing can bring them back to life.

If the watch you like comes with a factory metal bracelet, I’d actually recommend going for that version.

Why? Three main reasons:

- Genuine OEM bracelets are expensive to buy separately.

- Meanwhile, finding a good-quality leather strap is much easier and more cost-effective.

Rubber straps can also be great — comfortable and sporty — but the reality is that not many watches suit rubber straps. They mostly work well on dive watches or sports models.

So in the rest of this post, let’s focus on the most popular and versatile option — leather watch straps.

Sharing Our Experience With Leather Watch Straps

OEM Strap VS Handcrafted Straps VS Mass-produced budget straps?

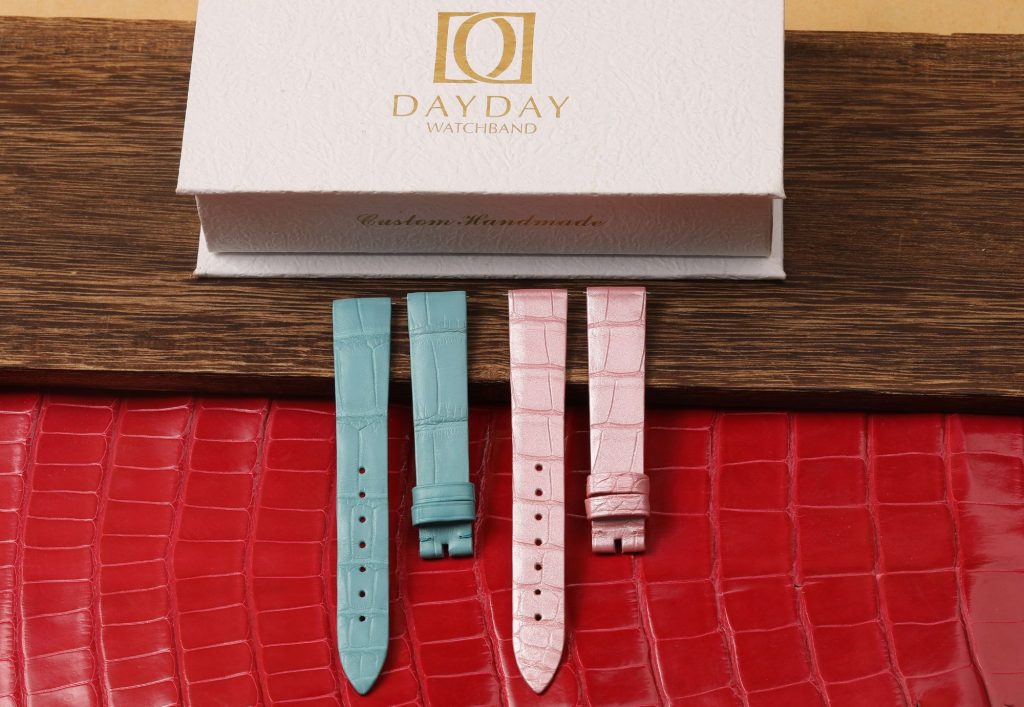

In the world of leather watch straps, they generally fall into three categories: OEM straps from the watch brands, handcrafted straps made by artisan workshops, and mass-produced budget straps.

If you care even a little about quality and longevity, we strongly recommend skipping the third category altogether.

OEM straps aren’t always the absolute best—though the craftsmanship is usually solid—but they are almost always the most expensive.

Another limitation is that OEM options tend to come in only classic colors like black and brown or blue, which makes it difficult to give your watch a truly fresh, personalized look simply by changing the strap.

Meanwhile, original watch straps are relatively expensive, and custom orders take at least 1-2 months.

That leaves the most exciting and versatile option—artisan-made, handcrafted straps.

But the quality in this category varies dramatically. The craftsmanship of different makers can be inconsistent, and the materials used range from premium hides to questionable leftovers.

So from the perspective of a custom strap maker, we’d like to share some practical insights on how to evaluate a good leather strap—focusing on three key aspects: leather quality, craftsmanship, and structural design.

Strap Key Point-Leather selection

Different types of animal leather, and even the same type but with different processing techniques, exhibit significant differences.

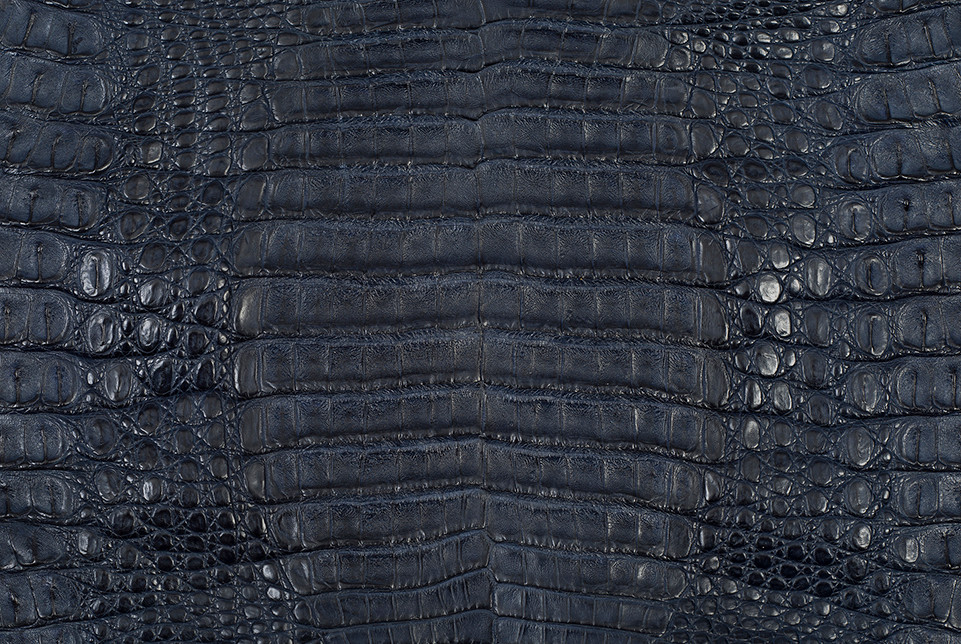

Let’s first discuss crocodile leather watch straps, often referred to as “platinum of leather,” which is also the most complex to understand.

First of all, crocodile leather comes in many varieties, and the differences in texture and price can be dramatic.

Here’s a simple overview of the main types to help you quickly understand the basics:

1. Porosus Crocodile (Saltwater Crocodile)

This species grows to a large size, which means bigger belly tiles and a clean, tightly arranged scale pattern—ideal for crafting larger leather goods.

However, Porosus hides are very rare and extremely expensive.

The most premium Hermès crocodile bags are made from Porosus.

2. American Alligator (Alligator mississippiensis)

Its most distinctive traits are: no visible pores, a soft and supple texture, neatly arranged belly scales, and clearly defined transitions between square and round scales.

It is less expensive than Porosus and is excellent for small leather goods and fine watch straps.

3. Nile Crocodile (Niloticus)

A step below Alligator in both quality and price.

The surface typically shows tiny pin-sized pores, though they don’t usually affect the overall appearance.

Still considered a relatively high-quality crocodile leather.

4. Siamese Crocodile

More affordable, but the belly scales are generally larger and rougher, with visible pores that give it a less refined look.

The difference between Siamese and American crocodile skin

5. Caiman

The most budget-friendly option.

Common caiman hides show noticeable bony structures, feel stiffer, and have less aesthetically pleasing belly scales.

Based on the above introduction, we can easily conclude that the best choice for making alligator watch straps is American alligator leather.

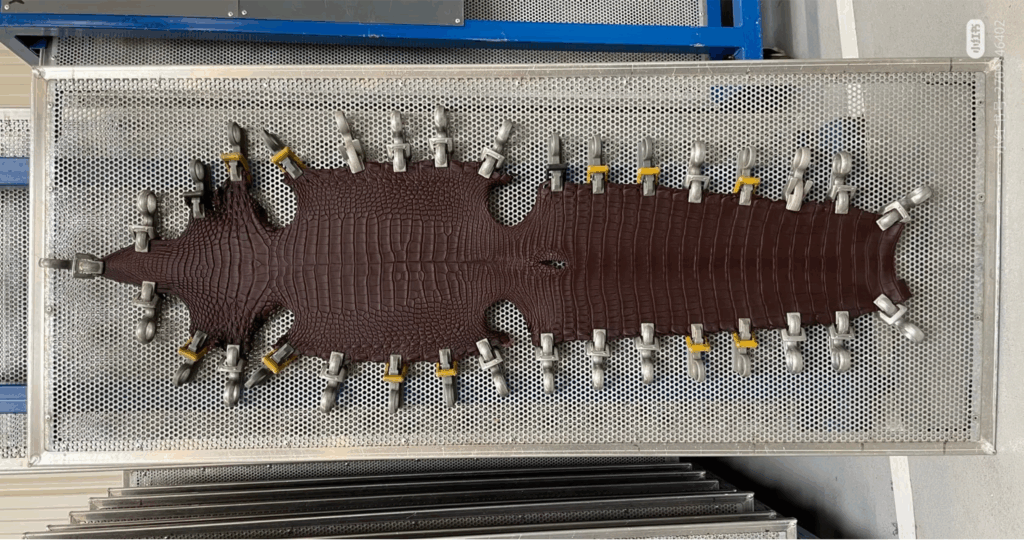

Secondly, the choice of location for the crocodile leather largely determines the overall aesthetics of the watch strap, sometimes even more so than the type of leather itself.

The best location for the strap is the bamboo-like pattern on the belly, followed by the bamboo-like pattern on the tail and the bamboo-like pattern on the chin.

The differences among the three are very obvious. The bamboo joint patterns on the abdomen are more square, and the leather is also softer and smoother.

The bamboo nodes at the tail are slightly harder than those at the belly, but the biggest difference is that the bamboo nodes at the tail are narrower and longer. Therefore, when making watch straps, two vertical lines often appear at the end of the strap.

The biggest problem with the bamboo joints on the chin is that the regularity of the bamboo joint pattern is poor; the joints are wider and the grid is smaller, which reduces their aesthetic appeal.

Even with square sacle sections on the abdomen, the placement of the material is crucial. The finished product should have relatively even patterns to be considered aesthetically pleasing.

Save you a lot of money, how to distinguish real alligator leather from alligator faux leather?

Watch Strap Craftsmanship Introduction

Aside from straps characterized by their ruggedness (like many of Panerai’s stylized straps), the craftsmanship of a watch strap must be as refined as possible.

It’s worth mentioning that, in terms of craftsmanship, brand-name straps aren’t necessarily better than handmade ones. This is because brand-name straps are mostly machine-stitched, and in many aspects, they cannot match the aesthetics of hand-stitched pieces. Such as, Every Daydaywatchband strap is handmade.

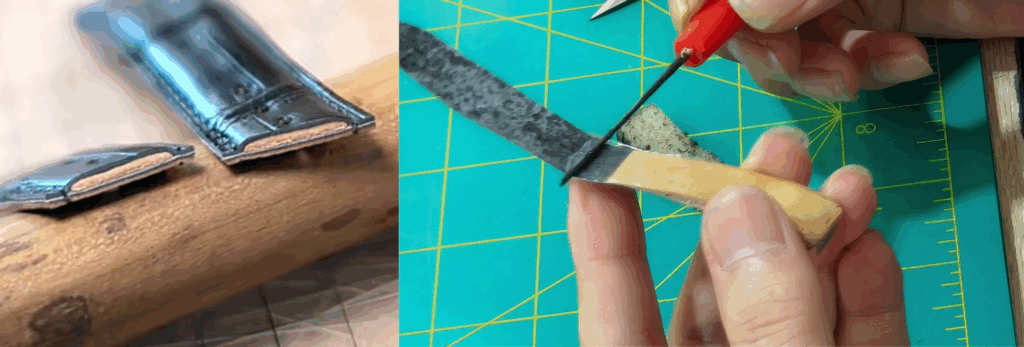

The quality of a watch strap’s craftsmanship involves many aspects, including stitching techniques, leather cutting, edge polishing, and edge coating, among which the stitching is the most easily perceptible.

The mainstream stitching method for handmade watch straps today is the “saddle stitch,” also known as the “horse saddle stitch,” originally a technique used in saddle making. Hermès popularized this method.

This stitching method has many advantages: the needle passes through the same hole twice, and the two threads cross each other, so even if one thread breaks accidentally, the entire seam won’t come undone, making it more durable than machine sewing. More importantly, the saddle stitch gives the stitch a beautiful wavy shape, while machine sewing produces a straight, stiff, and monotonous line.

Adding neatly arranged backstitches at the end of the strap also makes it look more refined.

- A well-made watch strap generally has the following characteristics

- no loose threads on the front

- reasonable spacing between the threads (too wide will appear rough, too dense will turn the wave pattern into jaggedness)

- consistent tension in the tensioning to ensure a uniform wave pattern

Other easily visible details, such as the edge paint being applied evenly and fully.

Common Watch Strap Structures

When you hold a watch strap in your hand, you only see the top and bottom layers, but it’s generally not a simple two-layer structure. Watch straps are categorized as either flat or bulged. Simply put, if the thickest part of the strap is thicker than the edge, it’s bulged; otherwise, it’s flat.

A sturdy watch strap typically has four or more layers. Besides the top and bottom layers, there are 2-3 internal layers:

First, there’s the middle layer, which adjusts the strap’s thickness. Some flat-bulged straps may not have this layer, but it’s necessary if the top and bottom layers are too thin. A strap that’s too thin lacks dimension; unless it’s an ultra-thin watch, a thin strap looks unbalanced and is prone to deformation. For bulged straps, this layer is crucial for creating a fuller, raised center. The choice between flat and bulged depends on personal preference; bulging offers more dimension and a simpler look.

Secondly, there’s the inner lining layer that wraps around the middle layer. This layer enhances the leather watch bands’s resilience, making it more durable, especially for expensive alligator leather, protecting it from stretching, deformation, or damage.

Thirdly, to further reinforce the strength of the lugs at the leather watch band end and clasp, some straps also have additional reinforcement layers in specific areas, generally made of more durable materials.

Complete guide | Getting rid of the smelly of leather watch straps

This concludes a relatively complete guide to choosing a leather watch strap replacement. If you’d like to order any watchstrap, daydaywatchband is a great choice. We offer a wide selection, competitive prices, exquisite craftsmanship, and professional customer service.

Welcome to contact us to get your custom-made watch strap.